Unitized Curtain Wall System

Introduction of unitized curtain wall system

Unitized curtain wall is the type of curtain wall with the highest degree of processing in the factory. In the factory, not only the vertical frames, horizontal frames and other components are processed, but also these components are assembled into unit component frames, and the curtain wall panels (glass, aluminum panels, stone panels, etc.) are installed in the corresponding positions of the unit component frames to form unit components. The height of the unit component should be equal to or greater than one floor and directly fixed on the main structure. The upper and lower frames (left and right frames) of the unit components are inserted to form a combination rod, and the joints between the unit components are completed to form an integral curtain wall. The main workload is completed in the factory, so that industrialized production can be carried out, greatly improving labor productivity and product quality.

Advantages of unitized curtain wall system

The unit type solves the problem of curtain wall leakage and adopts the "isobaric principle"; the force transmission is simple and can be directly hung on the embedded parts of the floor, which is easy to install. The unit components are processed and manufactured in the factory, and the glass, aluminum plate or other materials can be assembled on a unit component in the processing plant. It is easy to check, which is conducive to ensuring the overall quality of diversity, ensuring the engineering quality of the curtain wall, and promoting the degree of industrialization of the building. The unit curtain wall can be designed to achieve and maintain a double-layer sealing system. The structural design of the curtain wall unit component installation connection interface can absorb inter-layer displacement and unit deformation, and can usually withstand a large degree of building movement, which is particularly beneficial for high-rise buildings and steel structure buildings.

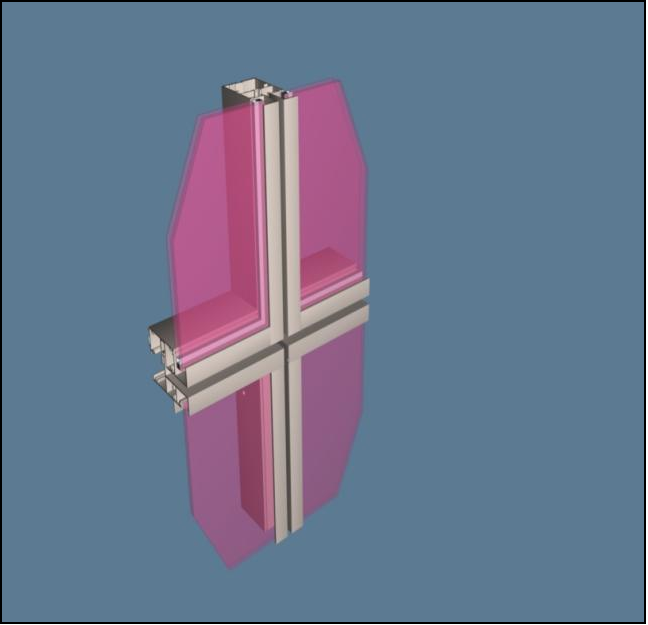

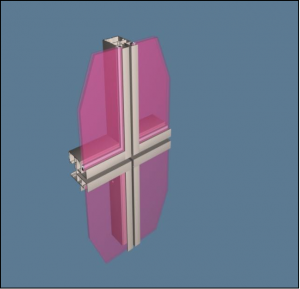

Structure of unitized curtain wall system

The unitized curtain wall is composed of many independent units. All the panel installation and inter-panel joint sealing inside each independent unit component are processed and assembled in the factory. The classification number is transported to the construction site for hoisting according to the order of project installation. The installation can be carried out simultaneously with the main structure construction (5-6 floors are enough). Usually each unit component is one floor high (or two or three floors high) and one grid wide. The units are inlaid with each other in a yin-yang structure, that is, the left and right vertical frames and the upper and lower horizontal frames of the unit components are inserted with the adjacent unit components, and the combination rods are formed by the insertion, thereby forming the joints between the unit components. The vertical frame of the unit component is directly fixed on the main structure, and the load it bears is directly transferred from the vertical frame of the unit component to the main structure.

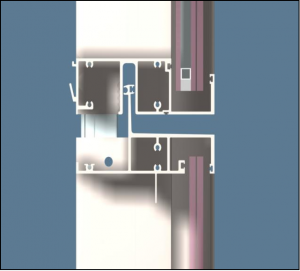

Node structure of unitized curtain wall system

1. According to the drainage method, it can be divided into: horizontal sliding type and horizontal locking type;

2. According to the installation method, it can be divided into: plug-in type and collision type;

3. According to the profile cross-section, it can be divided into: open type and closed type.

Features of unitized curtain wall system

1. The unit panels of the unit curtain wall can be processed and manufactured in the factory, which is easy to realize industrialized production, reduce labor costs, and control the unit quality; a large amount of processing and preparation work is completed in the factory, thereby shortening the curtain wall on-site construction period and engineering construction period, bringing greater economic and social benefits to the owner;

2. The male and female columns between the units are inlaid and connected, which has strong ability to adapt to the displacement of the main structure and can effectively absorb earthquake effects, temperature changes, and inter-layer displacement. The unit curtain wall is more suitable for super high-rise buildings and pure steel structure high-rise buildings;

3. The joints are mostly sealed with rubber strips, and weather-resistant glue is not used (which is the current development trend of curtain wall technology at home and abroad). It is not affected by the weather on the glue application, and the construction period is easy to control;

4. Since the unit curtain wall is mainly constructed and installed indoors, the adaptability of the main structure is poor, and it is not suitable for the main structure with shear walls and window walls;

5. Strict construction organization and management are required, and there is a strict construction sequence during construction. The installation must be carried out in the order of insertion. There are strict restrictions on the placement of construction machinery such as vertical transportation equipment used for main construction, otherwise it will affect the installation of the entire project.

Why Choose GKBM

Xi'an Gaoke Building Materials Technology Co., Ltd. adheres to innovation-driven development, cultivates and strengthens innovative entities, and has built a large-scale new building materials R&D center. It mainly carries technical research on products such as uPVC profiles, pipes, aluminum profiles, windows&doors, and drives industries to accelerate the process of product planning, experimental innovation, and talent training, and build the core competitiveness of corporate technology. GKBM owns a CNAS nationally accredited laboratory for uPVC pipes and pipe fittings, a municipal key laboratory for recycling of electronic industrial waste, and two jointly constructed laboratories for school and enterprise building materials. It has built an open scientific and technological innovation implementation platform with enterprises as the main body, market as the guide, and combining industry, academia and research. At the same time, GKBM has more than 300 sets of advanced R&D, testing and other equipment, equipped with advanced Hapu rheometer, two-roller refining machine and other equipment, which can cover more than 200 testing items such as profiles, pipes, windows&doors, floors and electronic products.