Respiratory curtain wall system

Introduction to Respiratory Curtain Wall System

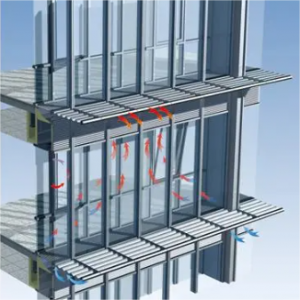

Breathing curtain wall, also known as double-layer curtain wall, double-layer ventilation curtain wall, heat channel curtain wall, etc., is composed of two curtain walls, inner and outer. A relatively closed space is formed between the inner and outer curtain walls. Air can enter from the lower air inlet and leave this space from the upper air outlet. This space is often in an air flow state, and heat flows in this space.

Features of the Respiratory Curtain Wall System

A ventilation layer is formed between the inner and outer curtain walls. Due to the circulation or circulation of air in this ventilation layer, the temperature of the inner curtain wall is close to the indoor temperature, reducing the temperature difference. Therefore, it saves 42%-52% of energy when heating and 38%-60% of energy when cooling compared to traditional curtain walls. Excellent sound insulation performance, up to 55dB.

Classification of Respiratory Curtain Wall System

1. Closed internal circulation system respiratory curtain wall

The closed internal circulation system breathing curtain wall is generally used in areas with colder winters. Its outer layer is generally completely closed, and is generally composed of thermal insulation profiles and hollow glass as the outer glass curtain wall. Its inner layer is generally a glass curtain wall composed of single-layer glass or openable windows to facilitate cleaning of the outer curtain wall.

2.Open external circulation system respiratory curtain wall

The outer layer of the open external circulation system breathing curtain wall is a glass curtain wall composed of single-layer glass and non-insulating profiles, and the inner layer is a curtain wall composed of hollow glass and thermal insulation profiles. The ventilation layer formed by the inner and outer curtain walls is equipped with air inlet and exhaust devices at both ends, and sunshade devices such as blinds can also be set in the channel.

Why Choose GKBM

Xi'an Gaoke Building Materials Technology Co., Ltd. adheres to innovation-driven development, cultivates and strengthens innovative entities, and has built a large-scale new building materials R&D center. It mainly carries technical research on products such as uPVC profiles, pipes, aluminum profiles, windows&doors, and drives industries to accelerate the process of product planning, experimental innovation, and talent training, and build the core competitiveness of corporate technology. GKBM owns a CNAS nationally accredited laboratory for uPVC pipes and pipe fittings, a municipal key laboratory for recycling of electronic industrial waste, and two jointly constructed laboratories for school and enterprise building materials. It has built an open scientific and technological innovation implementation platform with enterprises as the main body, market as the guide, and combining industry, academia and research. At the same time, GKBM has more than 300 sets of advanced R&D, testing and other equipment, equipped with advanced Hapu rheometer, two-roller refining machine and other equipment, which can cover more than 200 testing items such as profiles, pipes, windows&doors, floors and electronic products.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileWindows & Doors, Windows Upvc, Casement Profiles, Upvc Profiles, Sliding Profiles, Aluminum Profiles,