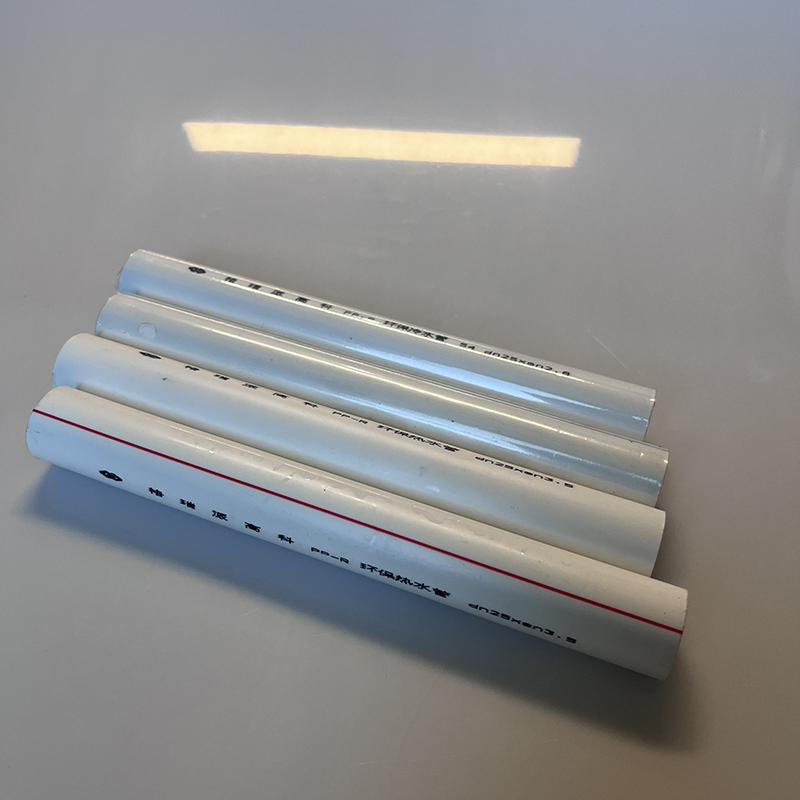

PPR Hot and Cold Water Pipe

PE-RT Floor Heating Pipe’s Classification

1.Excellent hygienic performance: The molecular composition of PP-R raw material only contains two elements: carbon and hydrogen. There are no harmful and toxic elements. The product is safe and hygienic.

2.Excellent quality: The product has reliable safety performance and the burst pressure can reach 6.0MPa. Quality is insured by Ping An Insurance Company.

3.Excellent thermal insulation performance: The thermal conductivity of PP-R pipe is 0.21 W/mK, which is only 1/200 of that of steel pipe. It effectively plays the role of pipe insulation and reduces heat loss.

4.Long service life: PP-R pipes can have a service life of more than 50 years at a working temperature of 70°C and a working pressure of 1.0MPa.

5.Supporting pipe fittings: There are more than 200 kinds of PP-R supporting pipe fittings, specifications: dn20-dn160, which can meet the requirements of various building water supply systems.

6.Copper parts are safe and hygienic: they are made of 58-3 copper material, with a lead content of less than 3%; the surface is nickel-plated, which does not breed bacteria; the copper thread fasteners are knurled, so they are not easily damaged during the installation process and do not cause pollution.

Why Choose GKBM PPR Hot and Cold Water Pipe

GKBM PPR hot and cold water pipes are produced with imported equipment from Germany's Krauss Maffei and Battenfeld. Cincinnati, and imported raw materials from South Korea's Hyosung and Germany's Basel Swiss factories. During the production inspection process, each batch of products is strictly inspected. The test is for the quality and safety of the products.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileUpvc Profiles, Windows Upvc, Sliding Profiles, Casement Profiles, Aluminum Profiles, Windows & Doors,