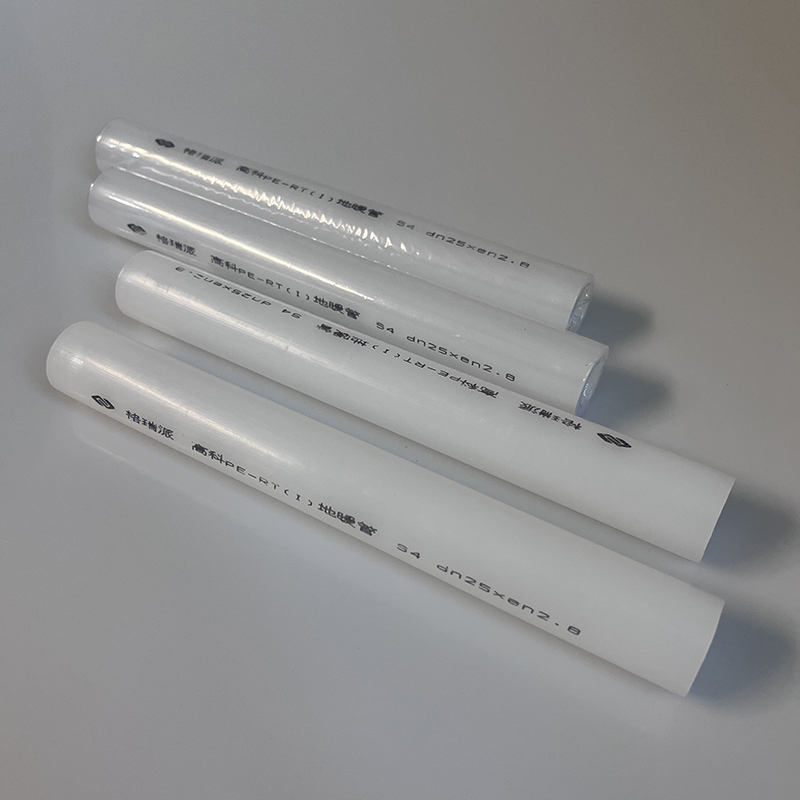

PE-RT Floor Heating Pipe

PE-RT Floor Heating Pipe’s Classification

There are a total of 16 products of PE-RT floor heating pipes, which are divided into 4 specifications from dn16-dn32. The products are divided into 5 grades according to pressure: PN 1.0MPa, PN 1.25 MPa,

PN 1.6 MPa, PN 2.0 MPa and PN 2.5 MPa. The water appliances are fully equipped and the products are used in the field of georadiant heating.

PE-RT Floor Heating Pipe’s Features

1.Excellent raw materials and quality assurance: raw materials imported from South Korea are used for production, and each finished product undergoes on-site air pressure testing at a pressure of 0.8MPa to ensure stable and reliable product quality.

2.Long service life: under the conditions of working temperature 70℃ and pressure 0.4MPa, it can be used safely for more than 50 years.

3.Good thermal conductivity: The thermal conductivity is 0.4W/mK, which is much higher than PP-R’s 0.21W/mK and PB’s 0. 17W/mK,which can save a lot of energy in heating applications.

4.educe the heating load of the system: the friction loss on the inner wall of the pipe is small, the fluid transport capacity is 30% higher than that of metal pipes of the same diameter, and the system heating pressure is small.

5.The connection method is flexible and easy to install: it can be hot-melt connection or mechanical connection. The connection method is flexible and easy to install, while PE-X can only be connected mechanically.

6.Low brittle temperature: The pipe has excellent low temperature resistance and can be constructed even under low temperature conditions in winter, and the pipe does not need to be preheated when bending.

7.Convenient construction and installation: it has good flexibility, and there will be no "rebound" phenomenon when bent, which is convenient for construction and operation; the pipe is coiled, which is easy to construct and install.

8.Excellent impact resistance: The impact resistance is 5 times that of PVC-U pipes. The product is not easily damaged during the construction process and has little safety hazard.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileSliding Profiles, Aluminum Profiles, Upvc Profiles, Windows & Doors, Casement Profiles, Windows Upvc,