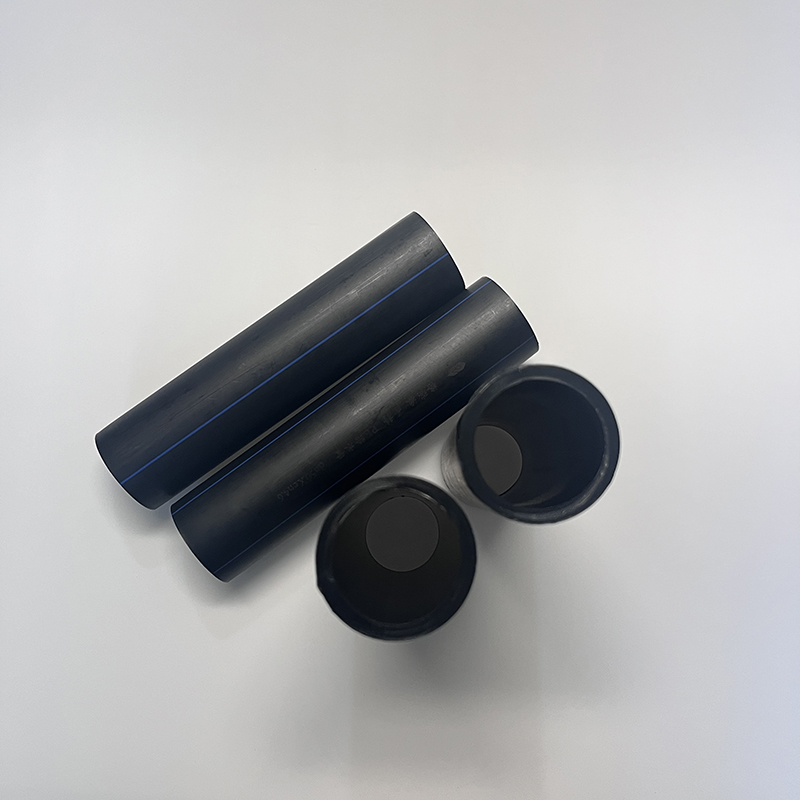

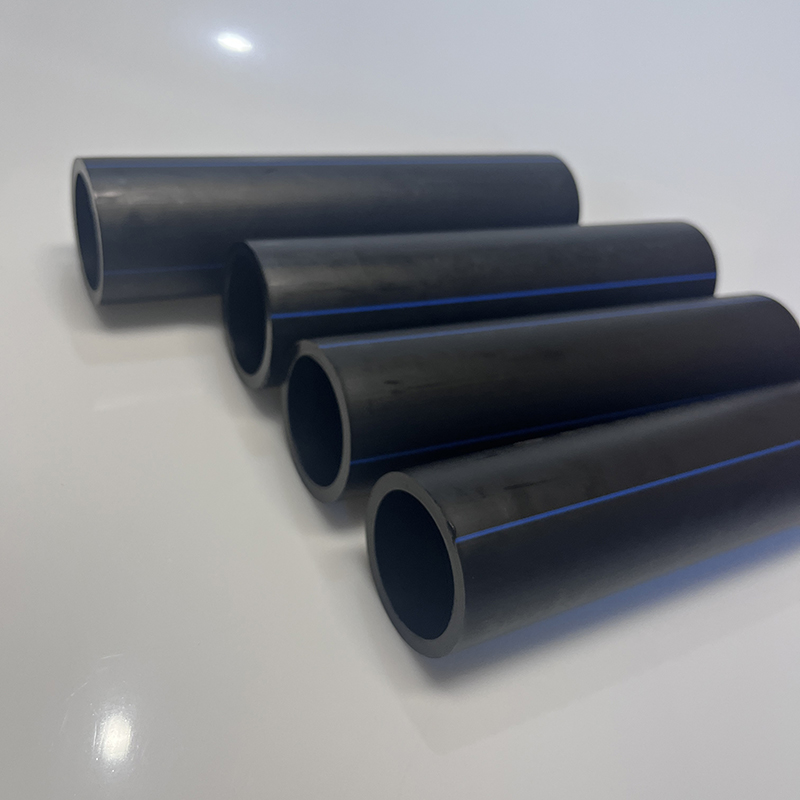

PE Water Supply Pipe

PE Water Supply Pipe’s Features

1.Long service life: the product contains 2-2.5% of uniformly distributed carbon black, which can be stored or used outdoors in the open air for 50 years; Inert material, good chemical resistance, the chemicals in the soil will not cause any degradation effect on the pipe.

2.Good impact resistance at low temperature: the temperature is extremely low, and it can be used safely at -60°C. Due to the good impact resistance of the material, the pipe will not be brittle and cracked during winter construction.

3.Excellent stress-cracking resistance and wear resistance: It has high shear strength, excellent scratch resistance and good wear resistance, which can effectively avoid damage to the piping system during construction.

4.Excellent flexibility, reducing installation costs: Good flexibility makes the product easy to be bend. In engineering, obstacles can be bypassed by changing the direction of the pipeline, reducing the amount of pipe fittings and installation costs.

5.Strong resistance to foundation settlement: The elongation at break of HDPE water supply pipe exceeds 500%, and it has strong adaptability to uneven settlement of the foundation and excellent anti-seismic performance.

6.Firm connection, no leakage: The piping systems are connected by electricity and hot melt, the pressure-bearing and tensile strength of the joint is higher than the strength of the pipe body.

7.Flexible construction methods: In addition to traditional excavation construction methods, a variety of new trenchless technologies can also be used for construction, such as pipe jacking, directional drilling, lining pipes, cracked pipes, etc.

Why Choose GKBM PE Water Supply Pipe

The PE water supply pipe produced by our company is made of PE100 imported from Borealis and Korea Petrochemical, and extruded by an extruder imported from Germany's Battenfeld. It is the only manufacturer in Northwest China that can produce dn630mm large-diameter PE water supply pipe; Products with good flexibility, corrosion resistance, lightweight and excellent impact resistance, etc., Pipe connection using hot melt socket, hot melt butt and electrofusion connection, etc., so that the pipe, fittings fused into one. The system is safe and reliable, with low construction cost. The specifications, dimensions and performance of PE pipes in line with the requirements of the GB/T13663-2000 standard. The hygienic performance conforms to the GB/T17219 standard and the relevant sanitation safety evaluation regulations of the State Ministry of Health, and has developed rapidly in engineering applications.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileWindows & Doors, Upvc Profiles, Casement Profiles, Aluminum Profiles, Sliding Profiles, Windows Upvc,