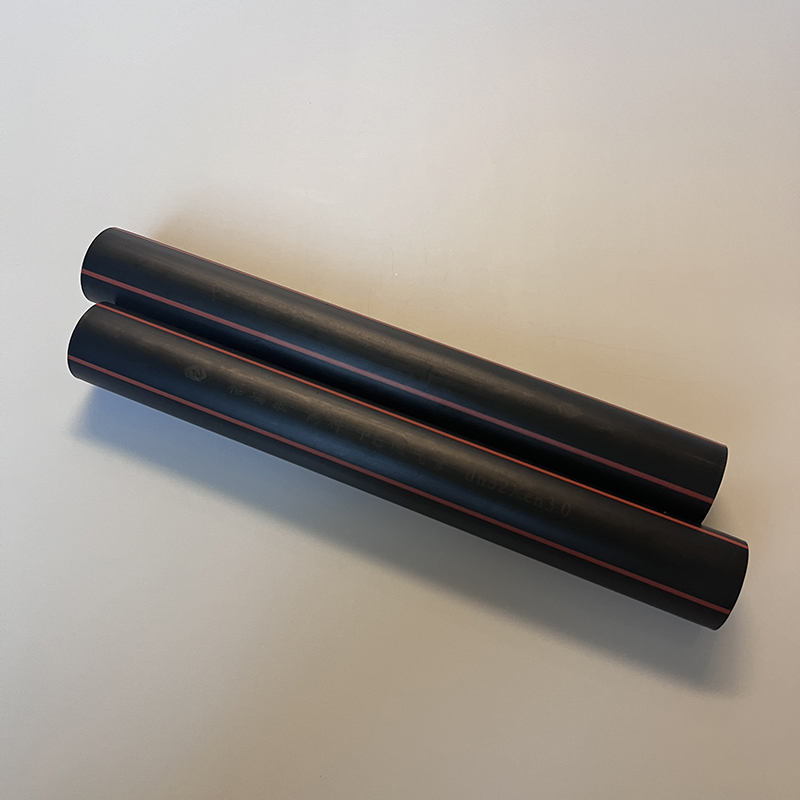

PE Gas Pipe

PE Gas Pipe’s Features

1.High performance: The production equipment uses the original imported production line from Battenfeld-Cincinnati, Germany. The raw materials are imported mixed special materials from Borealis ME3440 and HE3490LS. The product has high safety performance.

2.Stable product quality: The testing equipment for raw materials and finished products is complete, and the products are produced and inspected in strict accordance with the GB15558 . 1-2003 standard.

3.Firm connection, no leakage: The piping systems are connected by electrofusion pipe fittings, and the joints are firmly connected and will not leak.

4.Long service life: the product contains 2-2.5% of uniformly distributed carbon black, which can be stored or used outdoors in the open air for 50 years; Inert material, good chemical resistance, the chemicals in the soil will not cause any degradation effect on the pipe;

5.Excellent stress-cracking resistance and wear resistance: It has high shear strength, excellent scratch resistance and good wear resistance, which can effectively avoid damage to the piping system during construction.

6.Strong resistance to foundation settlement: The elongation at break of HDPE water supply pipe exceeds 500%, and it has strong adaptability to uneven settlement of the foundation and excellent anti-seismic performance.

PE Gas Pipe’s Classification

There are a total of 72 PE gas pipe products, which are divided into two types: PE80 and PE100. According to the maximum allowable working pressure, the products are divided into 4 grades: PN0.5MPa, PN0.3MPa, PN0.7MPa and PN0.4MPa. from dn32- dn400 a total of 18 specifications, mainly used in the transportation of natural gas.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileUpvc Profiles, Casement Profiles, Windows & Doors, Aluminum Profiles, Windows Upvc, Sliding Profiles,