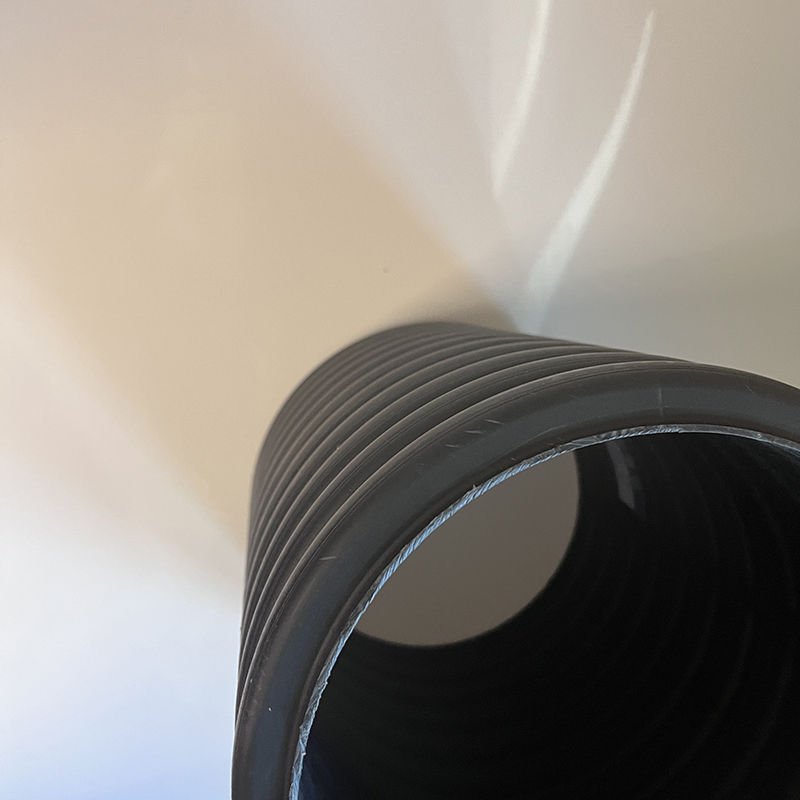

PE Double Wall Corrugated Pipe

PE Double Wall Corrugated Pipe’s Features

1.Ring corrugated structure: it has excellent mechanical properties of both rigidity and flexibility, high strength, compression resistance, bending resistance and impact resistance;

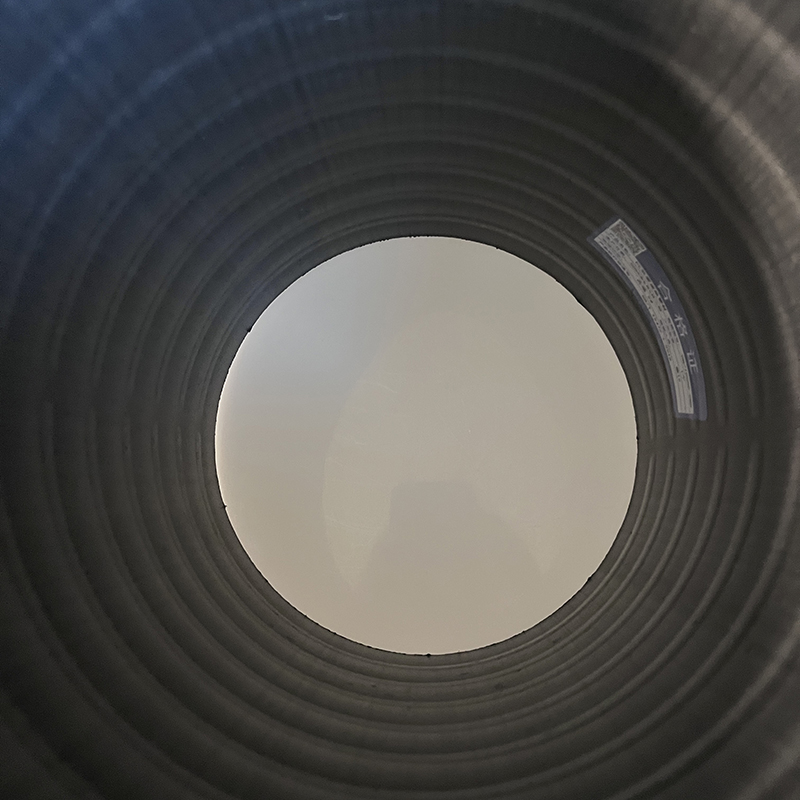

2. Smooth inner wall: large water flow, small fluid friction resistance, large flow rate, and no scaling;

3.Stable chemical properties: corrosion-resistant, non-toxic, non-polluting, and outstanding environmental performance;

4.Hollow rib structure: light weight, convenient construction, greatly reducing construction costs;

5.Operating temperature range: -60°C—+60°C.

6.It has a certain degree of flexibility and is suitable for uneven soil. The pipe can be laid directly in the trench prepared for bending without pipe Fittings.

7.The service life can reach more than 50 years, and the black outer wall has anti-ultraviolet and anti-aging properties.

8.100% recycling, saving resources for the country and protecting the environment.

PE Double Wall Corrugated Pipe’s Classification

There are a total of 8 products of PE double-wall corrugated pipes, divided into 4 specifications from dn200-dn500, and divided into two grades: SN2 and SN4, according to ring stiffness. Used in municipal and building rainwater pipes, underground drainage pipes, sewage pipes, ventilation pipes,etc.

Why Choose Gaoke PE Double Wall Corrugated Pipe

Gaoke Pipeline Production Base is located in Qianxian Industrial Park, Xianyang City, Shaanxi Province, China, covering an area of 235 acres. It has more than 100 sets of various domestic and foreign advanced extrusion production lines and injection molding production lines, more than 1,000 types of supporting molds, and an annual production capacity of more than 20 Thousands of tons. The products cover two major fields: municipal and construction, building drainage and rainwater pipe systems, building power pipeline systems, building water supply pipeline systems, building heating pipeline systems, municipal water supply pipeline systems, municipal drainage pipeline systems, natural gas pipeline systems, agricultural water conservancy pipeline systems, municipal With more than a thousand varieties of products in 10 series and 18 categories of power pipeline systems and municipal thermal pipeline systems, it is the most comprehensive comprehensive service provider in the domestic plastic pipeline industry.