In modern architecture and construction, curtain wall systems are becoming increasingly popular for their aesthetics, energy efficiency and structural versatility. Among the various options available, unitized curtain wall structures stand out as a state-of-the-art solution that brings many benefits to modern building projects. In this blog, we will take an in-depth look at the product introductions and features of unitized curtain wall structures, shedding light on their innovative design and practical benefits.

Introduction to Unitized Curtain Wall

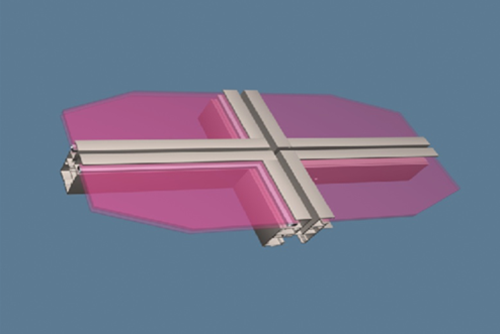

Unitized curtain wall is composed of a number of independent units, each independent unit assembly inside all the panels installed, sealing the joints between the panels are processed and assembled in the factory, classified and numbered according to the order of installation of the project transported to the construction site lifting, the installation of the construction can be synchronised with the construction of the main structure (a difference of 5-6 floors can be). Usually each unit assembly for a floor height (or two or three floors high), a compartment

width, unit and unit between the use of yin and yang mosaic structure, that is, the unit assembly of the left and right vertical frame, up and down the horizontal frame are and the neighbouring unit assembly pairs of inserts, through the pairs of inserts to form a combination of rods, so as to form a unit assembly indirectly meet. The vertical frame of the unit assembly is directly fixed on the main structure, and the loads borne by the vertical frame of the unit assembly are directly transferred to the main structure.

Features of Unit Curtain Wall

1. The unit plate of unit curtain wall is processed and made in the factory, which is easy to realise industrial production, reduce the labour cost and control the quality of the unit; a large number of processing and preparation work is completed in the factory, which can shorten the on-site construction cycle of the curtain wall and the construction cycle of the project, and bring greater economic and social benefits for the owners.

2. The male and female columns between the unit and the unit are inlaid and connected to adapt to the main structure of the strong displacement ability, can effectively absorb seismic effects, temperature changes, interlayer displacement, unit curtain wall is more suitable for ultra-high-rise buildings and pure steel structure high-rise buildings.

3. The joints are mostly sealed with adhesive strips, and weather-resistant adhesive is not used (which is the current development trend of curtain wall technology at home and abroad), so it is not affected by the weather on gluing, and the construction period is easy to be controlled.

4. As the unit type curtain wall is mainly installed in indoor construction, the adaptability of the main structure is poor, and it is not applicable to the main structure with shear wall and window wall.

5. Strict construction organisation and management is required, and there is a strict construction sequence during construction, which must be installed according to the order of pair insertion. The main construction of vertical transport equipment and other construction machinery with strict restrictions on the placement of the location, otherwise it will affect the installation of the entire project.

In conclusion, the unitized curtain wall system represents a paradigm shift in the field of building enclosure systems, and is a harmonious unity of form and function. Their product introductions and features demonstrate a commitment to excellence in design, performance and sustainability. As the demand for innovative architectural solutions continues to grow, modular curtain wall construction is a testament to the power of ingenuity and engineering in shaping the built environment. Whether it's a towering skyscraper or a boutique retail space, this cutting-edge system has the potential to redefine the way we perceive and interact with modern architecture.

Post time: Aug-16-2024