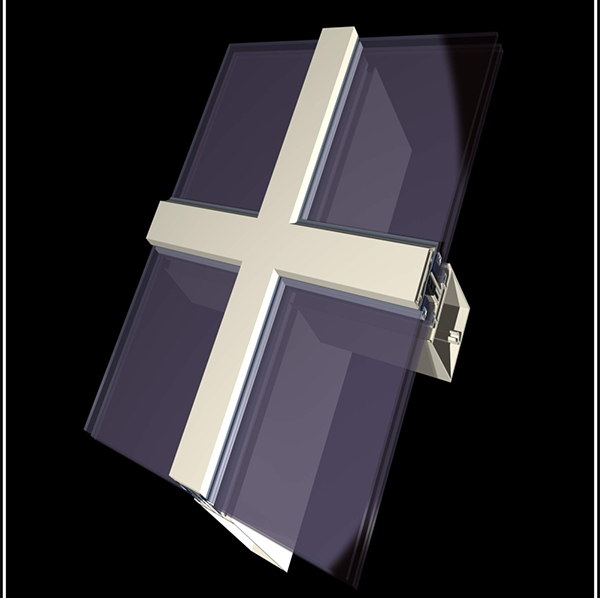

Frame curtain wall system

Introduction to frame curtain wall system

A glass curtain wall with a metal frame around the glass panel is called a frame curtain wall. It is divided into: exposed frame curtain wall, hidden frame curtain wall, and semi-hidden frame curtain wall according to the curtain wall form.

Features of frame curtain wall system

Frame glass curtain wall is flexible, convenient, simple to install, easy to adjust and disassemble, and easy to replace and maintain.

Installation method of frame curtain wall system

The vertical frame (or horizontal beam) of the frame curtain wall is first installed on the main structure, and then the horizontal beam (or vertical frame) is installed. The vertical frame and the horizontal beam form a frame. The panel material is processed into unit components in the factory and then fixed on the frame composed of vertical frame and horizontal beam. The load borne by the panel material unit component must be transferred to the main structure through the vertical frame (or horizontal beam). The more common form of this structure is: after the vertical frame and the horizontal beam are installed on site to form a frame, the panel material unit component is fixed on the frame. The panel material unit component is vertically connected to the column and horizontally connected to the horizontal beam, and the joint is treated with sealant to prevent rainwater penetration and air penetration.

The main node forms of the frame curtain wall system

1. Exposed frame: integral inlay groove type, combined inlay groove type, mixed inlay type;

2. Concealed frame: block type, full hanging type, semi-hanging type;

3. Semi-concealed frame: vertical exposed and horizontal concealed, vertical concealed and horizontal exposed.

Why Choose GKBM

Xi'an Gaoke Building Materials Technology Co., Ltd. adheres to innovation-driven development, cultivates and strengthens innovative entities, and has built a large-scale new building materials R&D center. It mainly carries technical research on products such as uPVC profiles, pipes, aluminum profiles, windows&doors, and drives industries to accelerate the process of product planning, experimental innovation, and talent training, and build the core competitiveness of corporate technology. GKBM owns a CNAS nationally accredited laboratory for uPVC pipes and pipe fittings, a municipal key laboratory for recycling of electronic industrial waste, and two jointly constructed laboratories for school and enterprise building materials. It has built an open scientific and technological innovation implementation platform with enterprises as the main body, market as the guide, and combining industry, academia and research. At the same time, GKBM has more than 300 sets of advanced R&D, testing and other equipment, equipped with advanced Hapu rheometer, two-roller refining machine and other equipment, which can cover more than 200 testing items such as profiles, pipes, windows&doors, floors and electronic products.