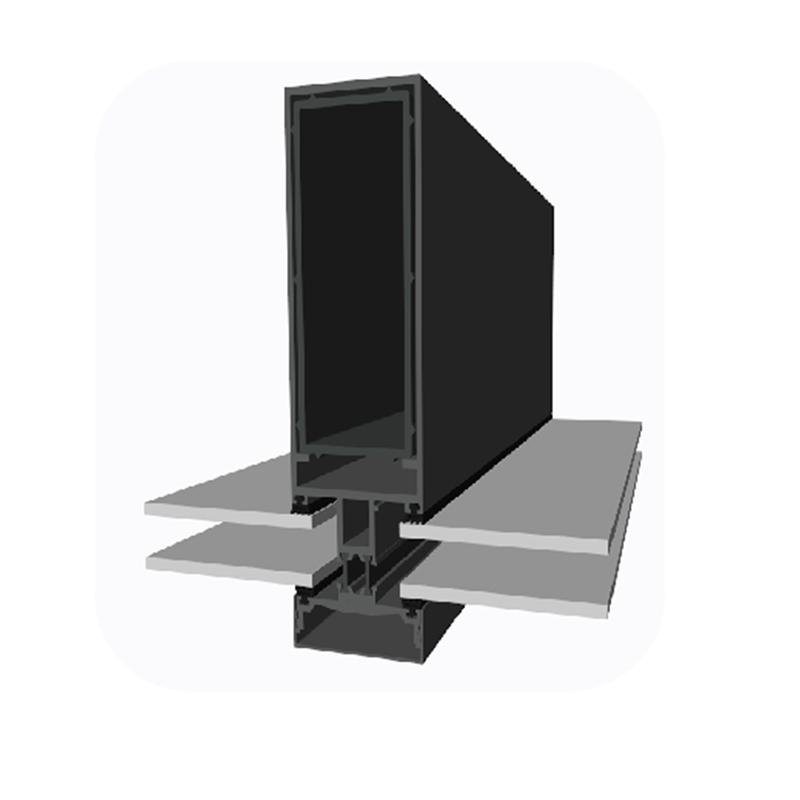

Exposed Frame Curtain Wall 120-180

GKBM Curtain Wall Product Series

There are various series of curtain wall profiles including 110, 120, 130, 140, 150, 160, 180, 200, etc., including fully visible, fully hidden, semi visible and semi hidden series. The column widths range from 50, 60, 65, 70, 75, 80, 100, etc., which can meet the design needs of different styles of curtain walls.

GKBM Product Quality Assurance

1. A sound quality management system;

2. A comprehensive quality control process;

3. High quality raw material guarantee: All aluminum rods are made from large domestic aluminum factories such as China Aluminum Corporation Lanzhou Aluminum Factory to ensure that the raw material composition meets national standards. The pre-treatment fluid is made from the German brand of Henkel, imported brands of Tiger and Aksu powder, domestic brands of Aiyue and Lansheng Fen, imported brands of thermal insulation strips are made from German Tainuofeng, and domestic brands are made from Wuhan Yuanfa and Ningbo Xingao;

4. Fully equipped testing instruments and equipment;

5. Accurate quality control points;

6. Rich experience in quality management: While emphasizing the management of quality processes, we also attach great importance to the inspection of quality results. The company has ten senior technical engineers and rich industry experience; There are more than 40 professional quality inspectors, distributed in the extrusion workshop for sawing and aging, the mold workshop for polishing and nitriding, the spraying workshop for upper and lower rows, and the deep processing workshop for gear cutting and strip composite packaging.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileAluminum Profiles, Upvc Profiles, Casement Profiles, Sliding Profiles, Windows Upvc, Windows & Doors,