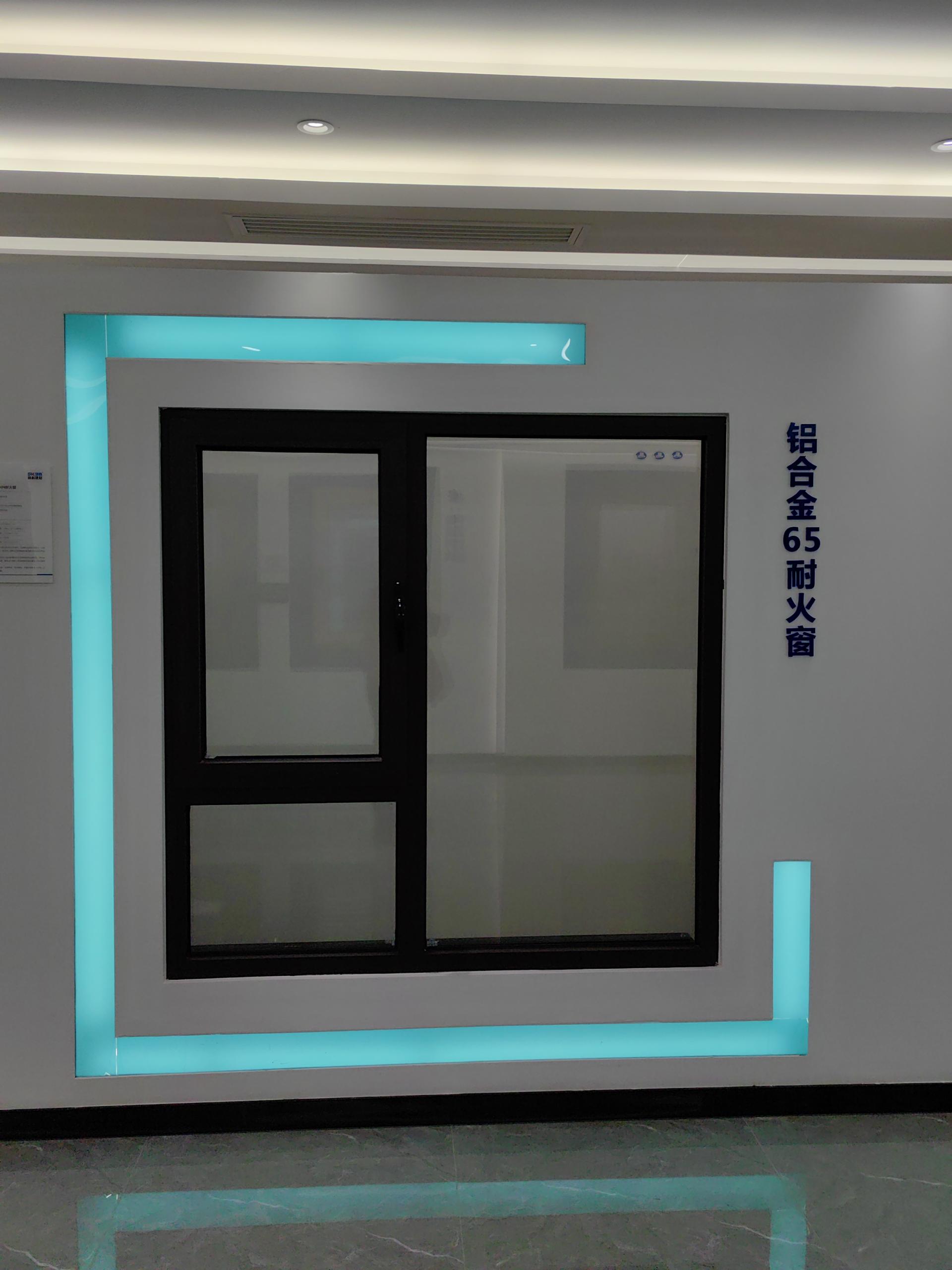

65 Fire Resistant Window

65 Fire Resistant Window’s Features

1.Use higher-performance fire-resistant accessory systems to make up for the fire-resistant needs of building exterior windows;

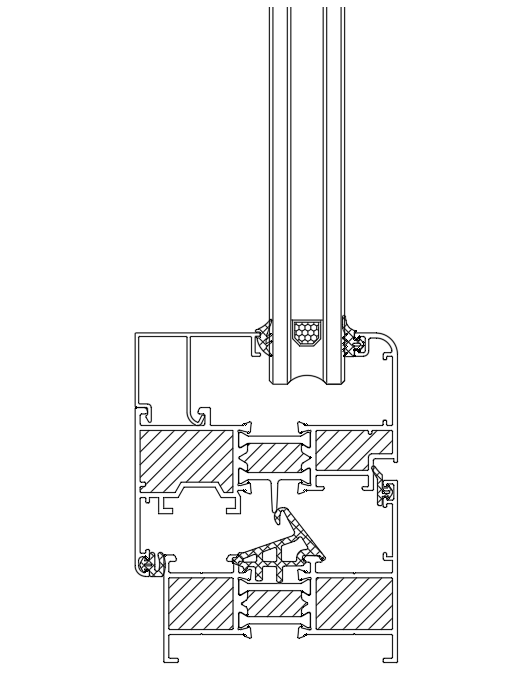

2.The C-shaped hook design of the profile facilitates the penetration of refractory expansion strips and other products, improves processing efficiency and effectively avoids degumming and peeling of refractory materials;

3.The insulation strips are refractory filled to enhance functionality while ensuring performance.

GKBM 65 Fire Resistant Window’s Design Ideas

1.The fire resistant window profiles based on the 65 series profiles, a higher performance fire-resistant accessory system is used on the basis of conventional system doors and windows. It not only has the high performance of system windows, but also makes up for the fire resistance requirements of building exterior windows, and is suitable for buildings with fire protection requirements.

2.The interior of the profile is filled with refractory materials to improve the thermal insulation performance of the entire window. Graphite-based intumescent fireproof strips, A1-level fireproof gaskets, and B1-level sealing silicone glue are used to form a good heat insulation barrier.

3.Special composite fireproof glass is used to make the It has both thermal insulation, sound insulation and fire resistance properties. It uses fire-resistant hardware with better steel quality and arranges multi-point locks to improve the sealing performance of doors and windows and effectively prevent fire and smoke from occurring in the gaps between frames and sash.

| Thermal insulation performance | K≤1.8 W/(㎡·k) |

| Water tightness level | 5 (500≤△P<700Pa) |

| Air tightness level | 6 (1.5≥q1>1.0) |

| Sound insulation performance | Rw≥32dB |

| Wind pressure resistance level | 8 (4.5≤P<5.0KPa) |

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileWindows & Doors, Sliding Profiles, Casement Profiles, Aluminum Profiles, Windows Upvc, Upvc Profiles,